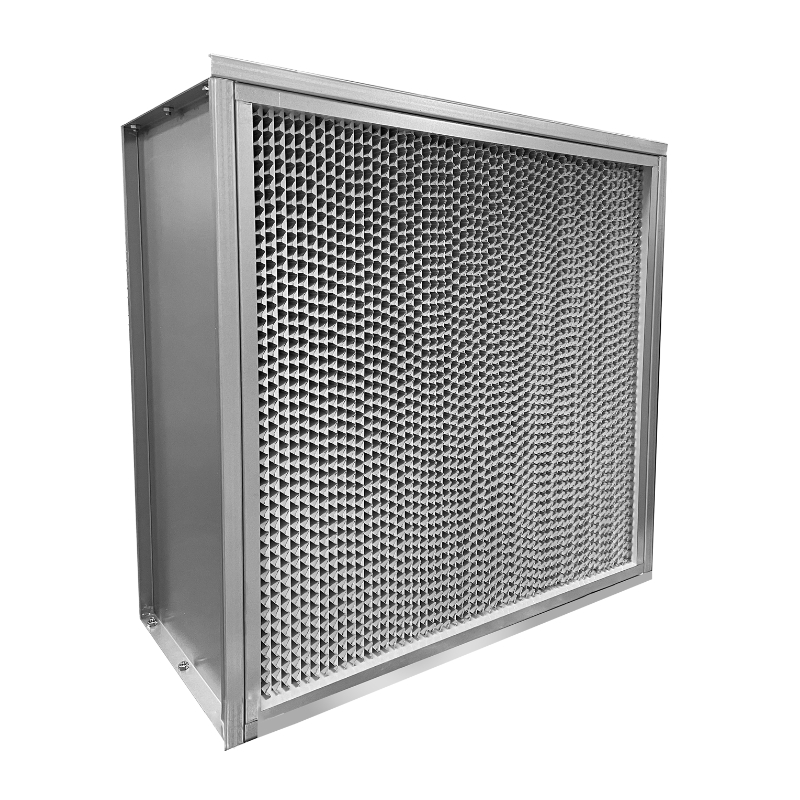

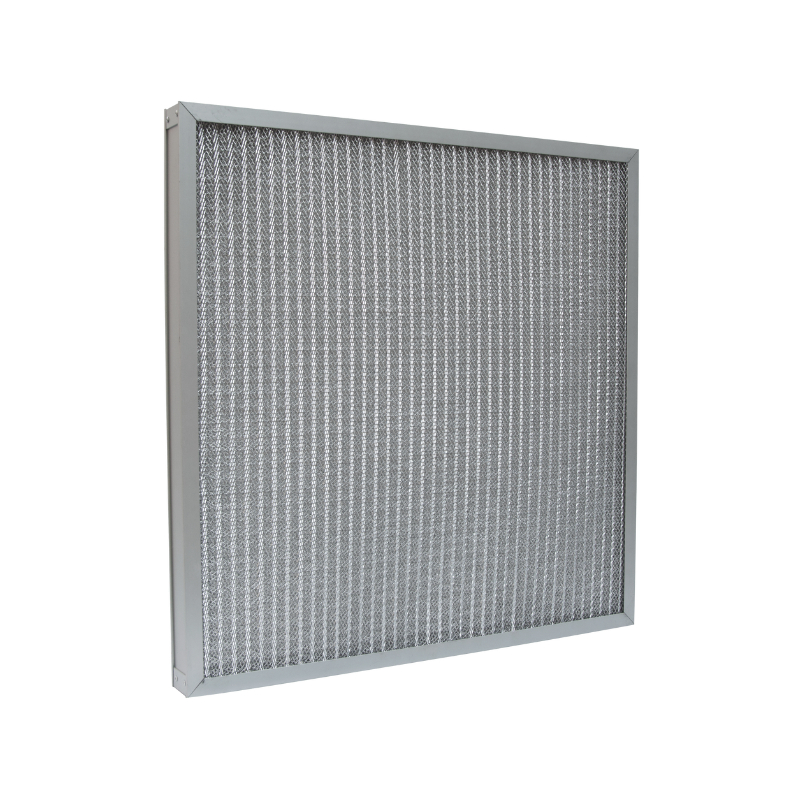

Alta eficiencia,buen sellado, baja resistencia, larga vida útil y Instalación y reemplazo livianos y convenientes. |5|

Diseño de pliegues en forma de cuña para evitar daños al medio filtrante.

Gran capacidad de retención de polvo y rendimiento estable, rentable y asequible.

Bajo consumo de energía, bajos costos operativos. Protección del medio ambiente verde, sin contaminación secundaria.

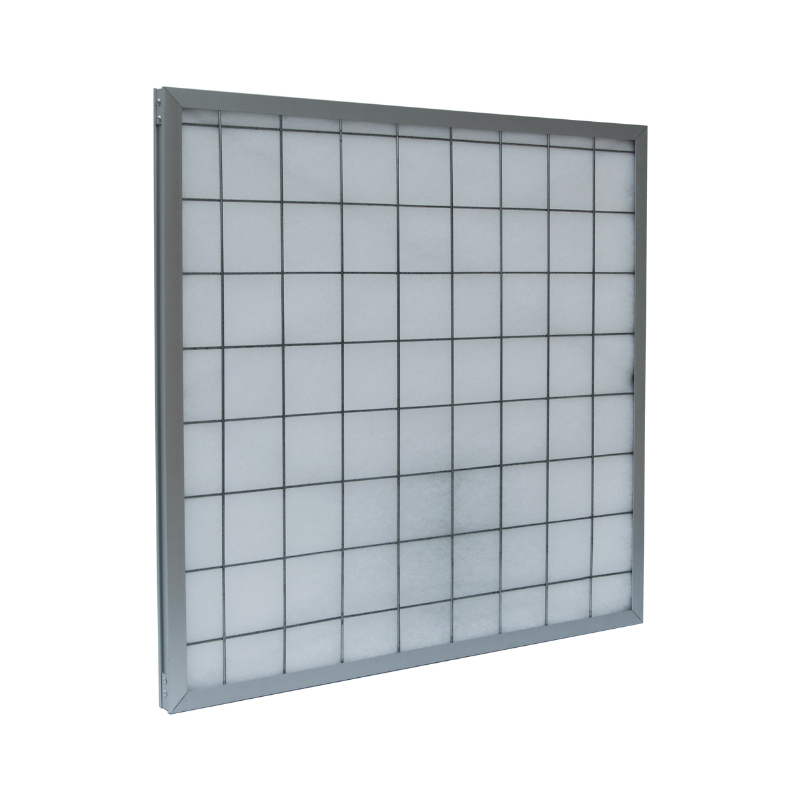

Ideal como prefiltro en unidades de tratamiento de aire, prolonga la vida útil de los filtros de alta eficiencia.

Se utiliza fieltro activo de alta calidad o fibra de carbón activado para satisfacer las necesidades especiales del medio ambiente.

Medios filtrantes lavables y reemplazables. Alta resistencia, gran volumen de aire, pequeña resistencia, alta capacidad de polvo.

Adecuado para ambientes con base ácida y alta resistencia a la humedad.

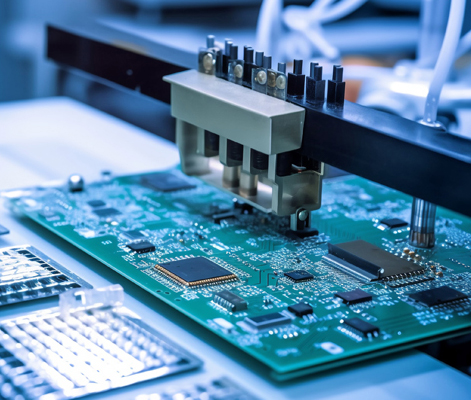

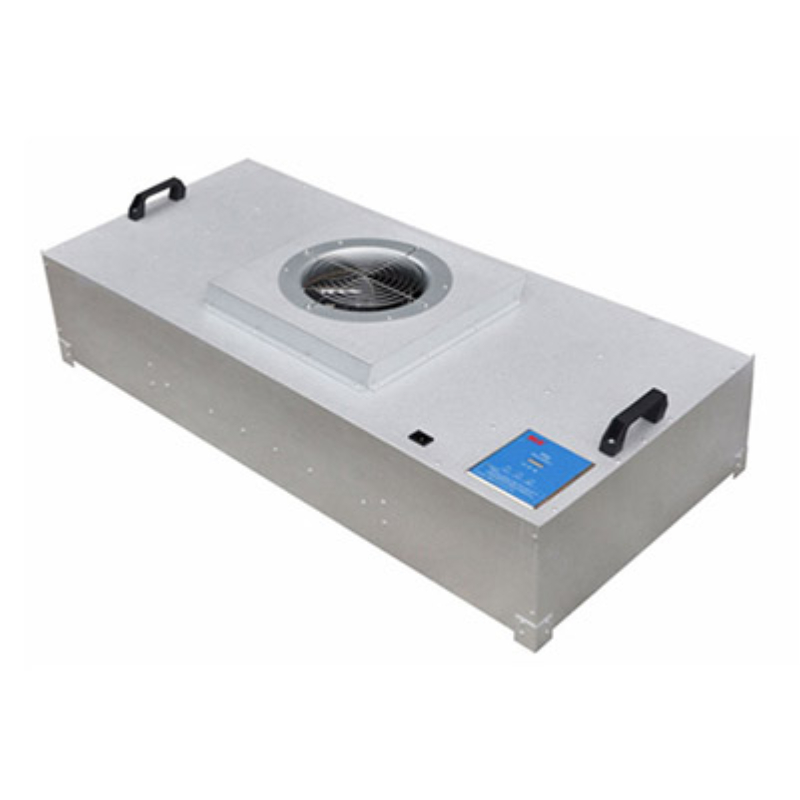

Normas ISO14644-1, con protección contra sobrecalentamiento para aumentar la seguridad de la aplicación de los usuarios.

La superficie es lisa y brillante, menor resistencia al aire y buen aislamiento acústico. Diseño especial de entrada de aire y reducción del ruido de forma eficaz.

Los diseñadores diseñaron cuidadosamente la placa difusora para garantizar que la velocidad del chorro de aire evite que el producto cree corrientes parásitas.

Ayuda a minimizar el riesgo de contaminación cruzada por las actividades del operador, garantizando la seguridad tanto del operador como de las muestras o productos que se manipulan.

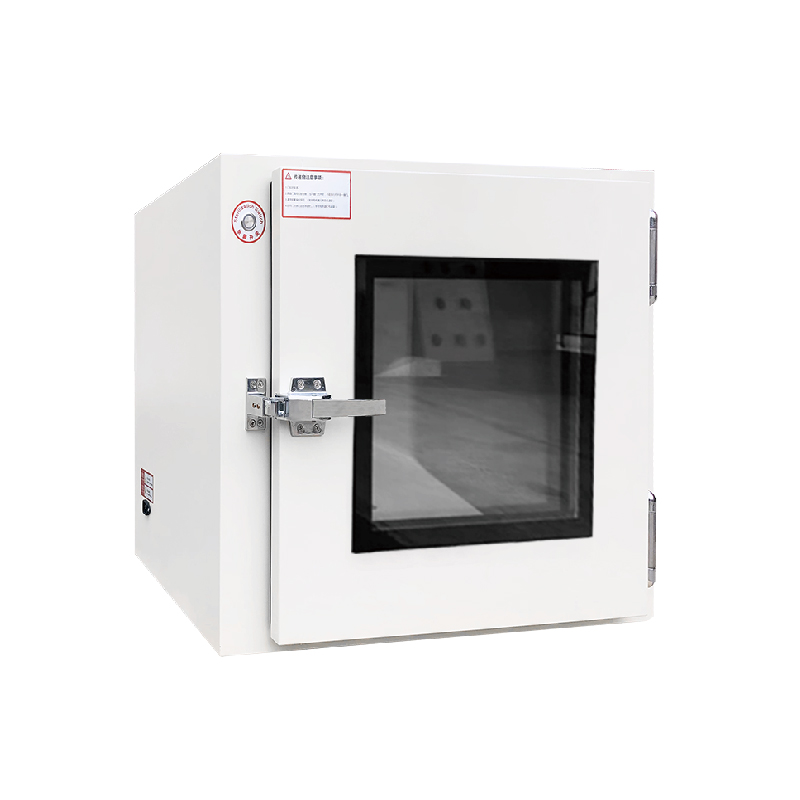

1. Interior de acero inoxidable pulido, plano, limpio y resistente al desgaste. La superficie de la caja de paso es de acero laminado en frío o acero inoxidable.

2. Las puertas en dos lados con dispositivo de bloqueo mecánico o electrónico permiten que dos puertas no puedan estar abiertas al mismo tiempo.

3. Caja de paso con tiras de sellado especiales para garantizar la estanqueidad.

♦ DISEÑO LIBRE

♦PRECIO DE FÁBRICA

♦FÁCIL INSTALACIÓN

♦SERVICIO POSTVENTA OPORTUNO

El uso de tecnología líder en capas de drenaje de resistencia que permite una distribución razonable del flujo de aire dentro de la sala limpia, garantiza eficazmente la limpieza interior.

El diseño es para suministro o descarga de aire a larga distancia, lo que tiene ventajas de libre mantenimiento, poca vibración, bajo nivel de ruido y suministro de aire de gran potencia. Colgar o montar en el suelo libremente.

Control inteligente. Tiempo de soplado regulable y sistema de enclavamiento. Fuerte efecto hermético. Boquillas de acero inoxidable en tres lados y gran volumen de aire. Ventilador de bajo ruido.